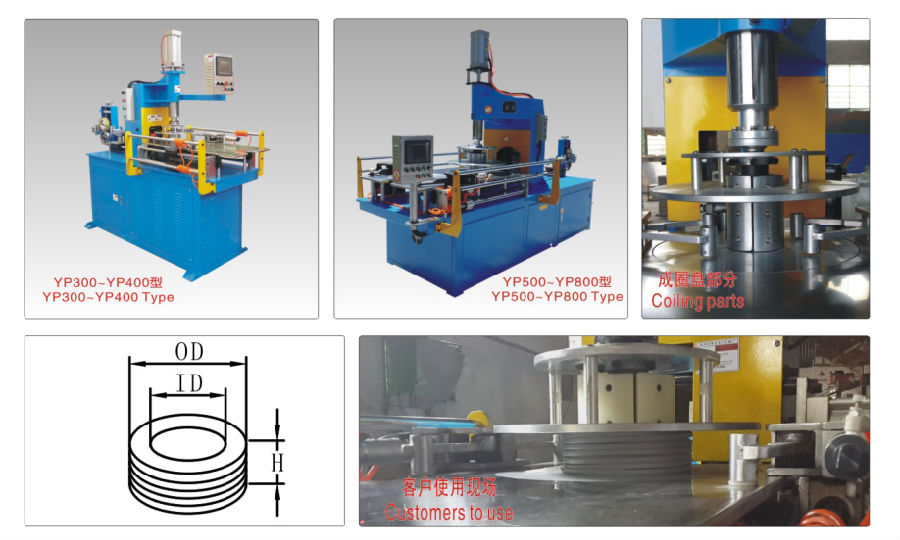

YP400-YP800 automatic looping

This machine is suitable for looping and tying of 0.5-10mm2 wires. The product has high production efficiency and the quality of the cable is at the advanced level of similar products. Compared with the traditional models, its main advantages are as follows:

a. Adopting automatic cable, the wire speed is the traditional machine Type 2-3 times.

b. With the fast tying device, the wires can be easily and quickly removed after being bundled on the machine, reducing labor intensity and saving labor time.

c. The three processes of winding, tying and plastic film packaging can be completed by one person, reducing labor costs.

d. The wire is supported by the province's strength, which ensures that the cable pitch is not affected by the size of the wire diameter, so that the wire is aligned and the quality of the cable is better.

Second, high-speed loop forming machine components and features:

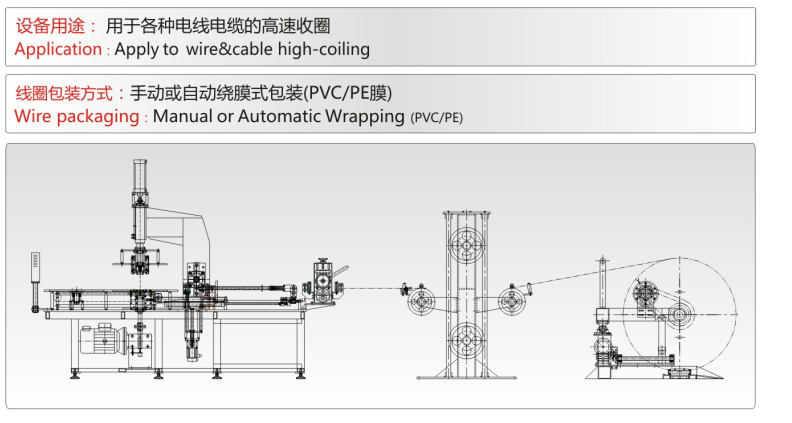

High-speed automatic cable looping machine from the line of force The take-up frame, the metering device, and the quick looping and tying device are composed of three parts, and the igniter and the caliper can be optionally used to detect the spark point and the wire diameter.

1, storage line tension release frame:

a. Use the storage line to keep the line tension constant.

b. Depending on the wire diameter of the different wires, the amount of force can be adjusted by the spring.

c. Lever brake, the lower the guide wheel of the rocker arm, the greater the resistance of the take-up reel, when the main body is set to the length of the ring for quick braking, the rocker guide wheel To the low position, the release line has a large resistance to the line, and the pay-off reel can brake in 1-2 seconds without messing up.

d. The handle-type upper and lower discs can be used to change the reel easily and quickly. The size of the reel is (customer size):

outer diameter

< p="">内孔outside width

center distance

2, electronic metering device:

a. Both the meter wheel and the pressure roller adopt a one-way bearing, and the wire can only move forward without retreating.

b. Use electronic metering to improve meter accuracy.

c. The surface of the meter wheel is plated with porcelain, and the pressure wheel is equipped with a rubber wheel to ensure that the wire is not damaged.

3, fast looping and tying the host:

a. Cable: automatic tension cable arranging device, the wire is pulled by the wire itself It can ensure that the line pitch is not affected by the size of the wire diameter, so that the wire line is neat and the cable quality is good.

b. Power: 3HP Taiwan TECO motor, speed up to 500 rev / min, can be operated by one person.

c. Control: 3HP Taiwan Dongyuan Inverter adopts frequency conversion control soft start and automatic brake technology. When starting up, avoid accelerating too fast to straighten the wire.

d. Automatic expansion and contraction can complete the expansion and loading and unloading in 2-3 seconds. The looped wire is tied on the machine and can be easily removed. It is easy to operate. Convenience.

e. Dimensions of wire after banding (size supplied by customer):

f With the electronic meter, the user can set the length of the loop as needed, and automatically stop when the meter reaches.

g. Optional wiring diameter tester and spark tester, the price is extra. Automatic alarm and timely shutdown when the outer diameter of the wire exceeds the tolerance or the surface is broken.

手机站

手机站 微信

微信