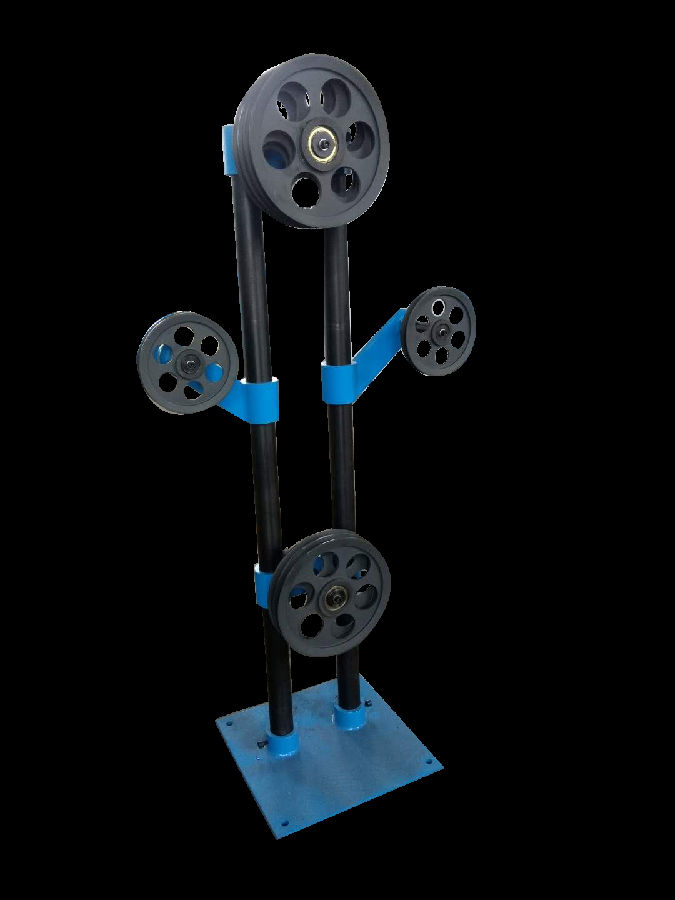

Vertical Straightener

Ginlay continues to absorb advanced technology from Europe, America and Japan, and the main components used in the machine are Sakamoto, Taiwan, the United States original products, can better produce the current advanced level of high-speed extruder and high-speed silicone extrusion production line, high-speed electric control cutting machine, high-speed stranding machine and high-speed electric control stranding machine, into Cable machine. The automatic control system of the vertical straightening machine requires three functions.

1) Knowledge acquisition function: acquire and store the empirical knowledge of the operator's selection parameters, and the operator selects the process parameters according to personal experience. Used to represent the operator's personal experience in a mathematical form and build a knowledge base to store these digital experience knowledge.

2) Shape detection function: Real-time online acquisition of the straightening information of the straightening machine into and out of the shape, with the development of optical measurement technology and image technology, can be from the surface of the plate surface video The flatness information of the plate shape is extracted. The metal uses video processing technology.

3) Parameter selection function: Using the stored empirical knowledge, combined with the shape data obtained by the shape detection system, select a set of process parameters that are most suitable for shape straightening, and establish knowledge. After the library, establish a mapping relationship. According to a certain algorithm, the relationship between the flatness of the sheet and the optimum process parameters can be obtained. With this mapping, different sheet flatness can be mapped to the process parameters that best fit the flatness.

手机站

手机站 微信

微信